I, Dr. Cheryl Kasdorf, have joined with TerraCycle to collect and return for recycling a lot of the packaging of your supplements that would be wasted.

This offer is limited to the brands of the parent company sponsoring this program. They are

- Pure Encapsulations®

- Douglas Laboratories®

- Klean Athlete®

- Genestra Brands®

- Pharmax®

- UNDA

- Wobenzym

TerraCycle is on a mission to Eliminate the Idea of Waste® in the packaging of your supplements and much more.

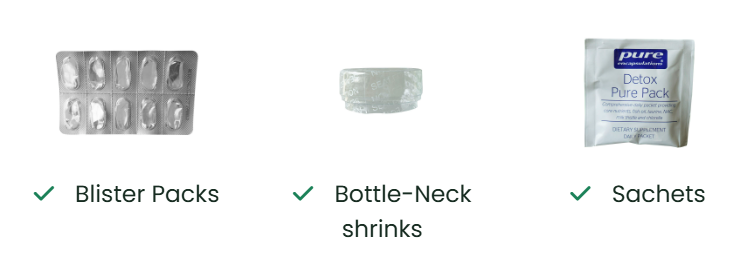

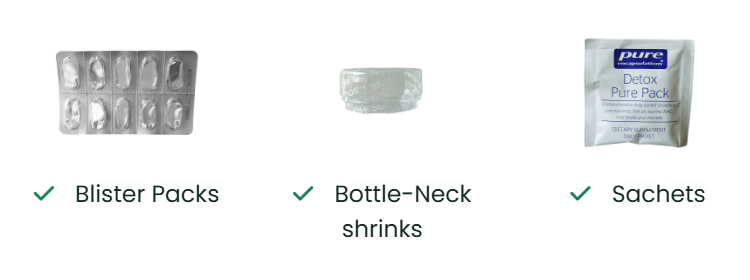

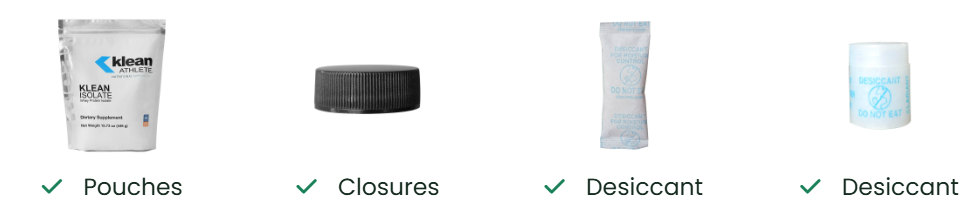

What TerraCycle takes for recycling

Typically, there are parts of the supplement packaging that you would normally throw away because local facilities do not recycle it. These are precisely what can be recycled in this program, including:

- plastic scoops

- neck shrinks

- droppers

- inner seals

- pouches/sachets

- blister packs

- desiccants

- bottle closures

- shipping materials.

Collect them all and deposit them in my office in the designated box! It’s that simple.

The packaging does not need to be cleaned before dropping it off, but please remove as much of the remaining product as possible.

When a bottle is marked with “1” or “2”, it is usually accepted at your local recycler, and TerraCycle does not need to take it.

Recycling is a step in the right direction

Let’s face it, recycling is not a perfect solution. Waste starts way upstream in the production cycle.

However, it is a major improvement over disposing of our waste in landfills. It beats burning it up through incineration.

Recycling’s main benefit is that it reduces the need to extract new materials from the Earth. For an average product, over 90 percent of the negative environmental impact comes from extracting and refining the raw materials from which it is made.

Eliminate the Idea of Waste

Usually, what makes something recyclable depends on whether your local recycling company can make a profit recycling it.

If the cost of collecting and processing the waste is lower than the value of the resulting raw material, it will likely be locally recyclable. If the cost is higher, then it likely won’t be.

The good news is that the technology exists to recycle most trash. In addition, TerraCycle knows how to design a business model to make it practical to recycle.

TerraCycle works with brands, retailers, and other stakeholders who fund the recycling process to make it smooth and practical.

For 20 years they’ve been on a journey to move the world from a linear economy to a circular one.

Continuing Innovation

TerryCycle creates first-of-their-kind solutions in recycling, recycled content, and reuse.

Recycling: Their first recommendation is always that manufacturers design their products or packages to be locally recyclable.

If that is not possible, TerraCycle partners with brands to create free recycling programs. This program that I am asking you to participate in is designed to recycle the items listed above with no cost to me or you.

Recycled content: The next step in zero waste is to work with manufacturers to help them make their products or packages from waste.

This generates demand for recycled content, which, along with recycling, creates a recycling-based circular economy.

Reuse: They also help companies move from recycling to reuse. Through Loop, TerraCycle has developed a global reuse platform that allows brands to easily develop reusable packaging. Then they enable retailers to make those products easily available to consumers.

As reuse scales, the need for TerraCycle recycling programs will diminish. The Earth applauds this transition. TerraCycle is investing many resources to achieve this outcome.

How these materials are recycled

Once collected, the listed brands of nutritional supplement packaging are cleaned and separated by material type.

Once sorted by category, the different material types are sent to third-party partners to process the materials into usable forms.

Plastics are the largest category of material Terracycle collects. These are made smaller by being shredded or ground. Then they are sorted by type and melted and reformatted into pellets, flakes, or a powder format. This is what is sold for re-use.

Metals and aluminum are shredded and smelted into metal sheeting, ingots, or bar stock.

Glass is crushed and melted. Clear glass is used in new glass bottles. Colored glass is used in brick, cement, or concrete applications.

After they recycle the waste into raw materials, it’s sold to manufacturing companies who produce the end product and complete the recycling journey.

These end products may include outdoor furniture and decking, plastic shipping pallets, watering cans, storage containers and bins, tubes for construction applications, and much more!

Note that they strictly control the movement of materials through each part of the recycling process to maintain a recycling chain of custody. This allows them to track and confirm where materials were sent and why.

Join Me!

Simply drop off anything on the list above from the brands listed to the designated box in my office.

I take it from there!